Primary Industry

Feed Production

Artificial Insemination

Beef and Dairy Production

An integrated production system for beef and dairy cattle,

covering everything from feed production to nursing, raising, and fattening.

Harnessing the rich natural environment and favorable climate of Kyushu, Kamichiku Group raises a wide range of beef cattle—including Japanese Black (Kuroge Wagyu), crossbreeds, and Holsteins—through a fully integrated production system.

We oversee the entire livestock value chain within the Group, encompassing feed production, cattle breeding, nursing, rearing, fattening, dairy farming, and pig farming.

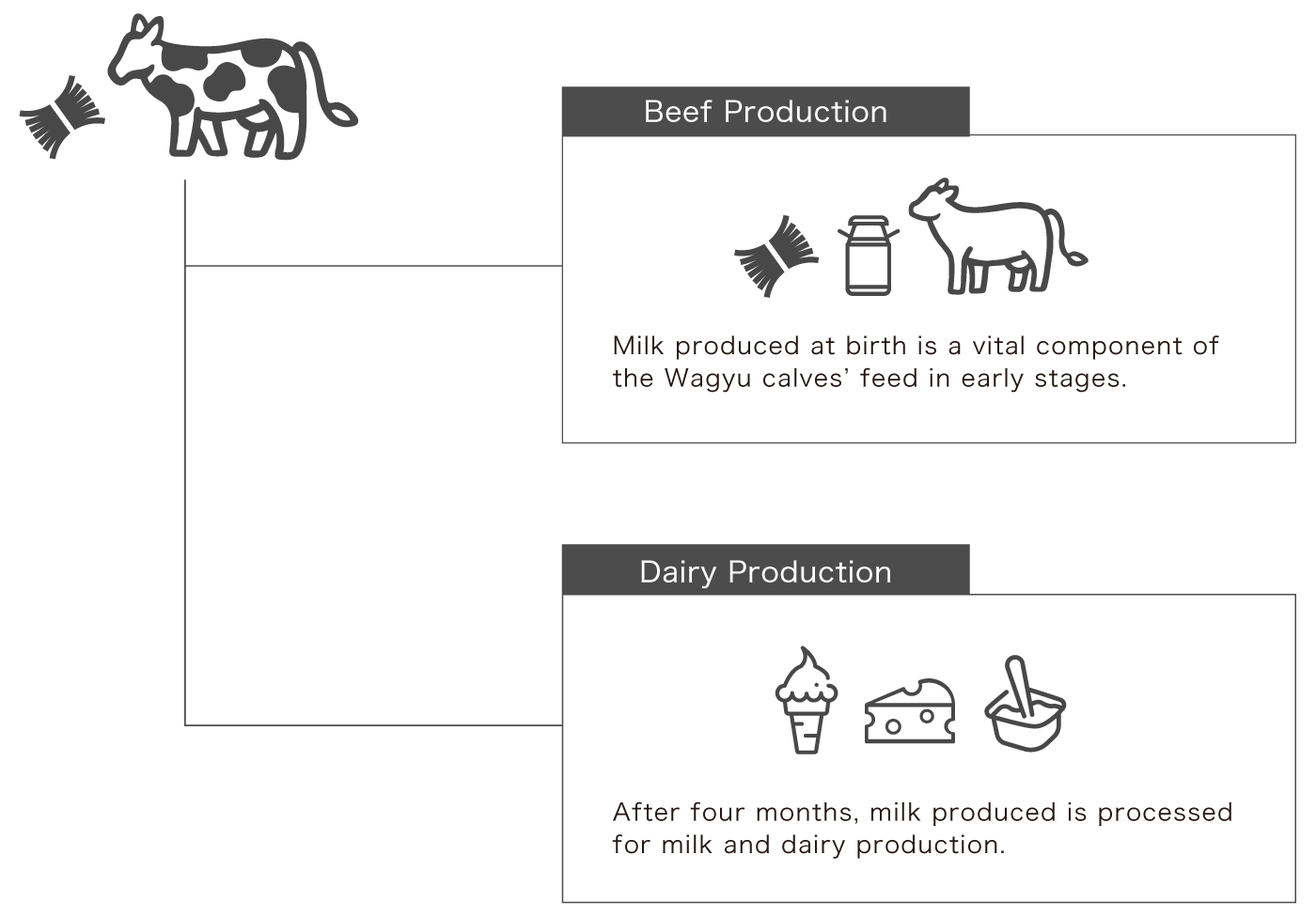

Our in-house compound feed facility (TMR Center) enables the production of carefully formulated, high-quality feed, significantly reducing one of the major cost drivers in livestock operations.

By controlling every stage of production, we ensure a stable, resilient livestock business while consistently creating high value-added products. This integrated approach underpins a sustainable and future-oriented agricultural management model.

A fully integrated in-house system from breeding and nursing to rearing and fattening

By formulating original feed tailored to each growth stage of the cattle, we ensure healthy animals and high-quality, flavorful meat.

Practicing animal welfare and introducing smart livestock farming (Utilizing IoT and AI)

Enhancing and streamlining cattle rearing and breeding management through data utilization

Kamichiku Farm Original Feed

「Fermented TMR Feed」

Driven by our commitment to providing safe and nutritious feed throughout every stage of our cattle’s lives—from birth to shipment—we have developed our own original Fermented TMR (Total Mixed Ration) feed.

This nutrient-rich feed is made using forage and rice grown by contract farmers across Kyushu, along with food production by-products sourced from local businesses. This not only enhances nutritional value but also helps reduce production costs in a sustainable way.

Sustainability is at the core of our approach. By utilizing fallow land to grow feed crops and returning compost to our farmers, we promote a circular, eco-friendly livestock farming system that works in harmony with nature.

Note: TMR = Total Mixed Ration

What is the TMR Center?

In collaboration with roughage producers across Kyushu and local food companies, we produce high-quality feed at low cost, utilizing food byproducts and other sustainable resources to create a more efficient and eco-friendly feed production system.

This approach not only supports local businesses but also contributes to reducing waste and promoting a circular economy.

Commitment to Feed Determines the Quality of Meat

One bite is all it takes to taste the difference.

That is the proof of our commitment to feed.

We believe that the feed we provide plays a vital role in the health, growth rate, and ultimately the meat quality of our cattle.

Through years of experience, we've learned that by prioritizing feed, we can produce meat that is

tender, rich in flavor, and distinguished by its unique fat quality.

For example, we use highly digestible feed and a custom blend formulated to reduce stress and promote a well-balanced nutritional profile.

We carefully select high-quality pasture and grains, making seasonal adjustments and fine-tuning the feed to suit each individual animal.

These extra steps, taken with care and precision, are what lead to the production of truly high-quality beef.

High-Quality Feed for Optimal Performance

We utilize feed rice and other grains cultivated by contracted farmers in Kyushu to ensure safe and reliable feed. By revitalizing idle farmland, we promote sustainable livestock farming in partnership with the local community.

Carefully Raised, Healthy Cattle

Our feed is specially formulated to support cattle health and minimize stress. We make seasonal and individual adjustments to provide an optimal, high-quality breeding environment.

Flavorful, High-Quality Meat

Each bite delivers a deep, savory umami, beautifully balanced by delicate, high-quality fat that melts cleanly on the palate, leaving a refined, elegant finish. We’re confident you’ll taste the difference from the very first bite.

Key Features and Advantages of the TMR Center

Optimizing Local Resources for Sustainability

By actively using local agricultural by-products such as shochu lees, beer lees, and rice straw, we reduce environmental impact and lower costs.

Customized Nutritional Solutions

We design custom nutrition plans tailored to each animal’s growth stage and health status, enhancing cattle well-being and driving improvements in meat quality.

Stable Supply and Labor Efficiency

By delivering a reliable supply of custom-formulated feed, we ease the burden of feed production for farmers, driving operational efficiency and reducing labor demands.

Integration within Our Complete In-House System

As a key part of our six-faceted industrialization model, the TMR Center is integral to our fully in-house operations, from feed production to beef processing.